Industrial Warehouse Monitoring Dashboard

Frankfurt, Germany – Logistics & Supply Chain – AI-Development & Consulting

Problem to Solve

A leading supply chain company in the Frankfurt region faced a persistent challenge: its maintenance teams lacked real-time visibility into the operational health of key industrial assets deployed across the facility network. With 29 machines running simultaneously, emerging faults were often detected only after performance had already degraded or a unit had stopped entirely. Teams relied on manual checks, delayed sensor exports, and fragmented internal tools. Despite multiple attempts to streamline workflows, issues continued to appear without warning — triggering unplanned downtime, slowing material flow, and forcing the organization to operate reactively rather than strategically. The company needed a unified system capable of continuously monitoring all critical machines, detecting early signs of abnormal behavior, and translating raw sensor data into clear, actionable insights for operators, supervisors, and maintenance planners.

Our Solution

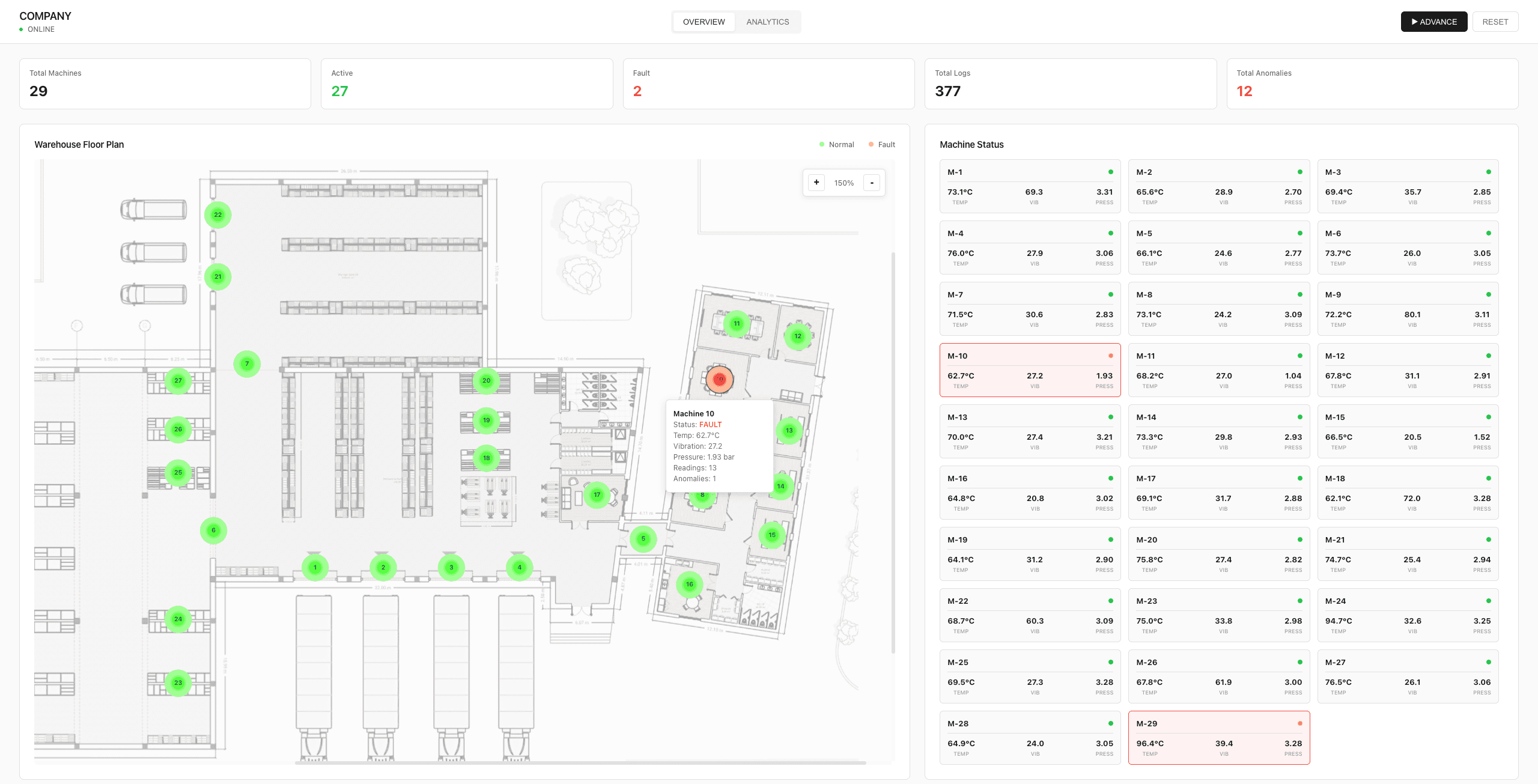

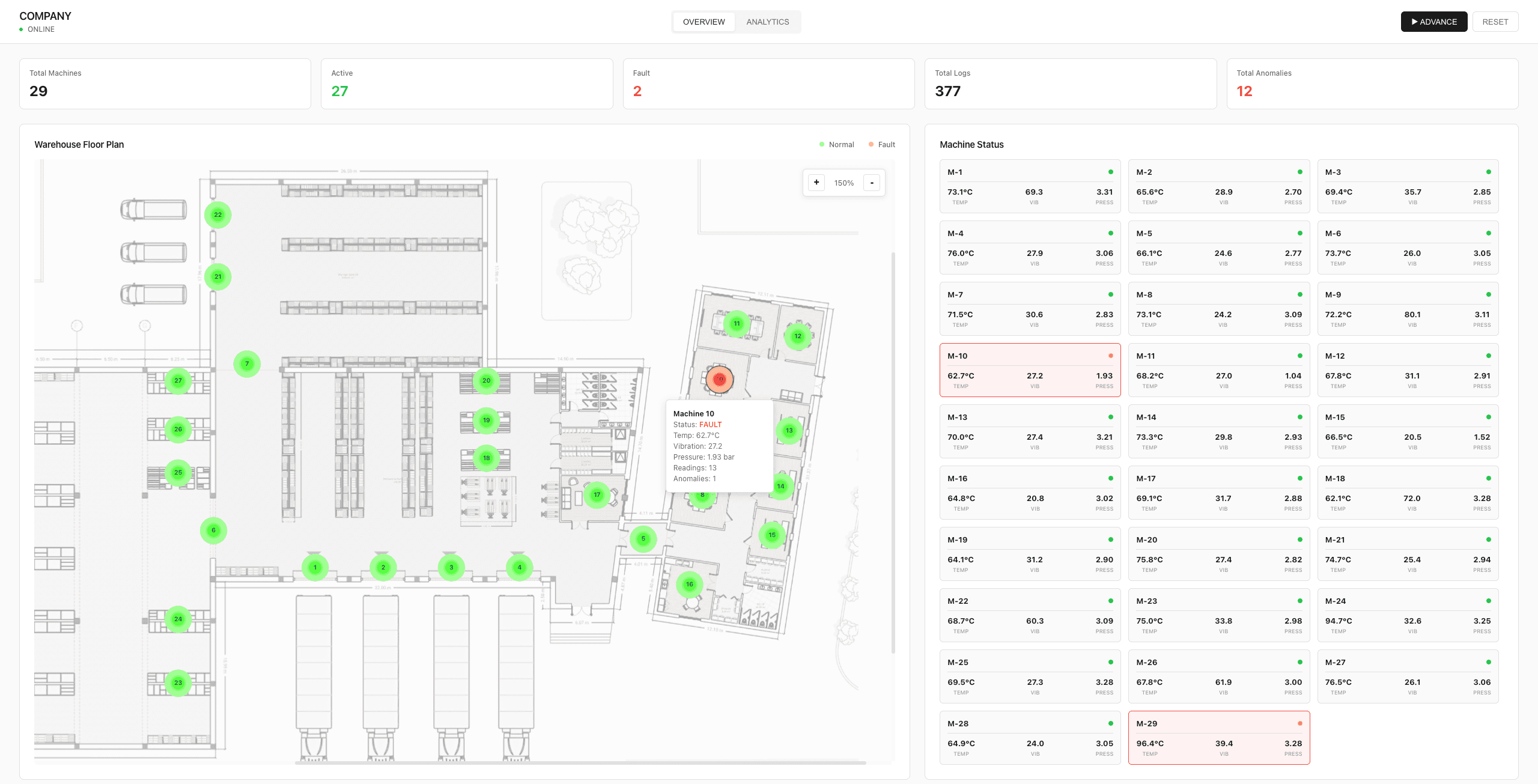

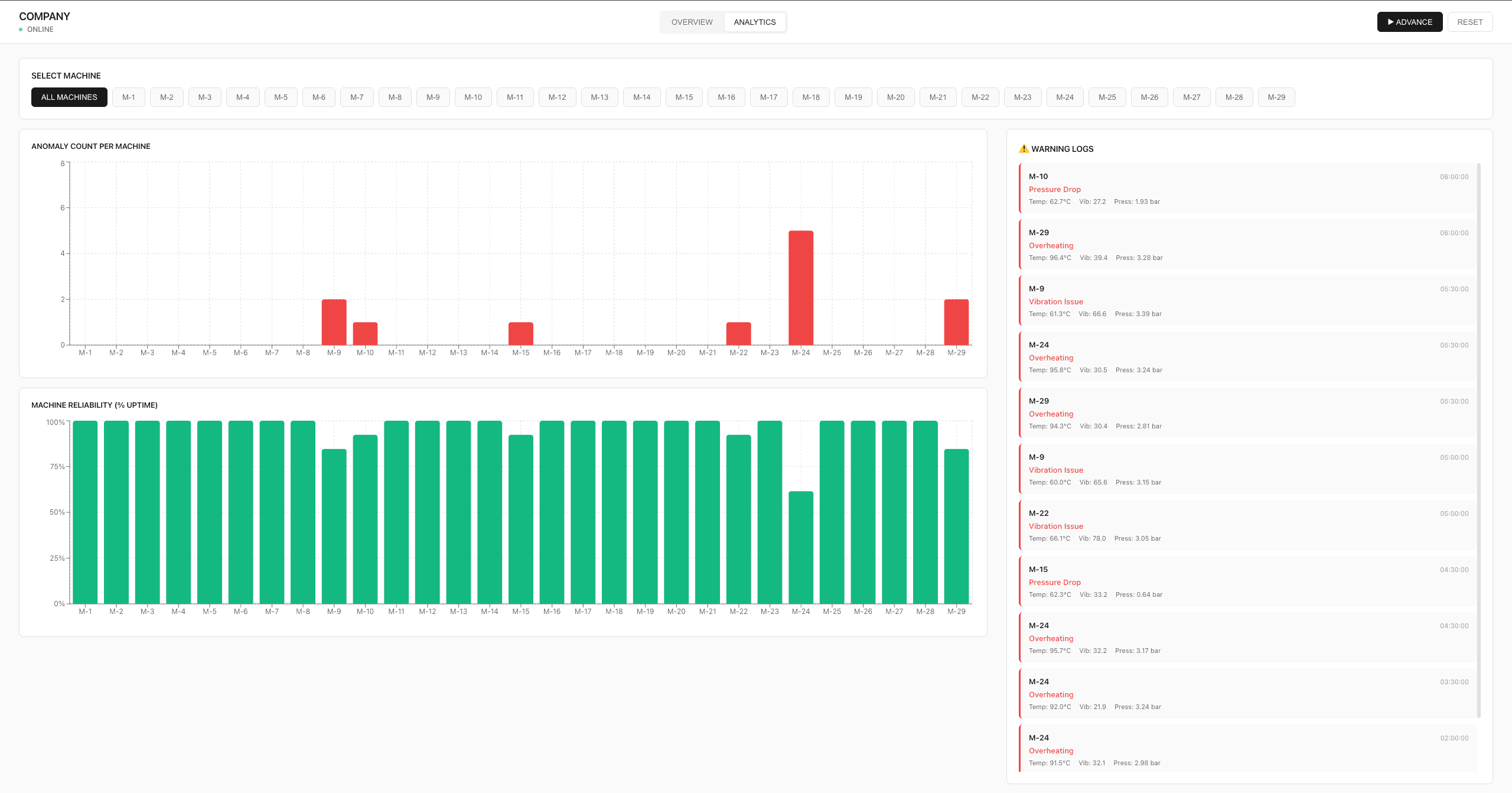

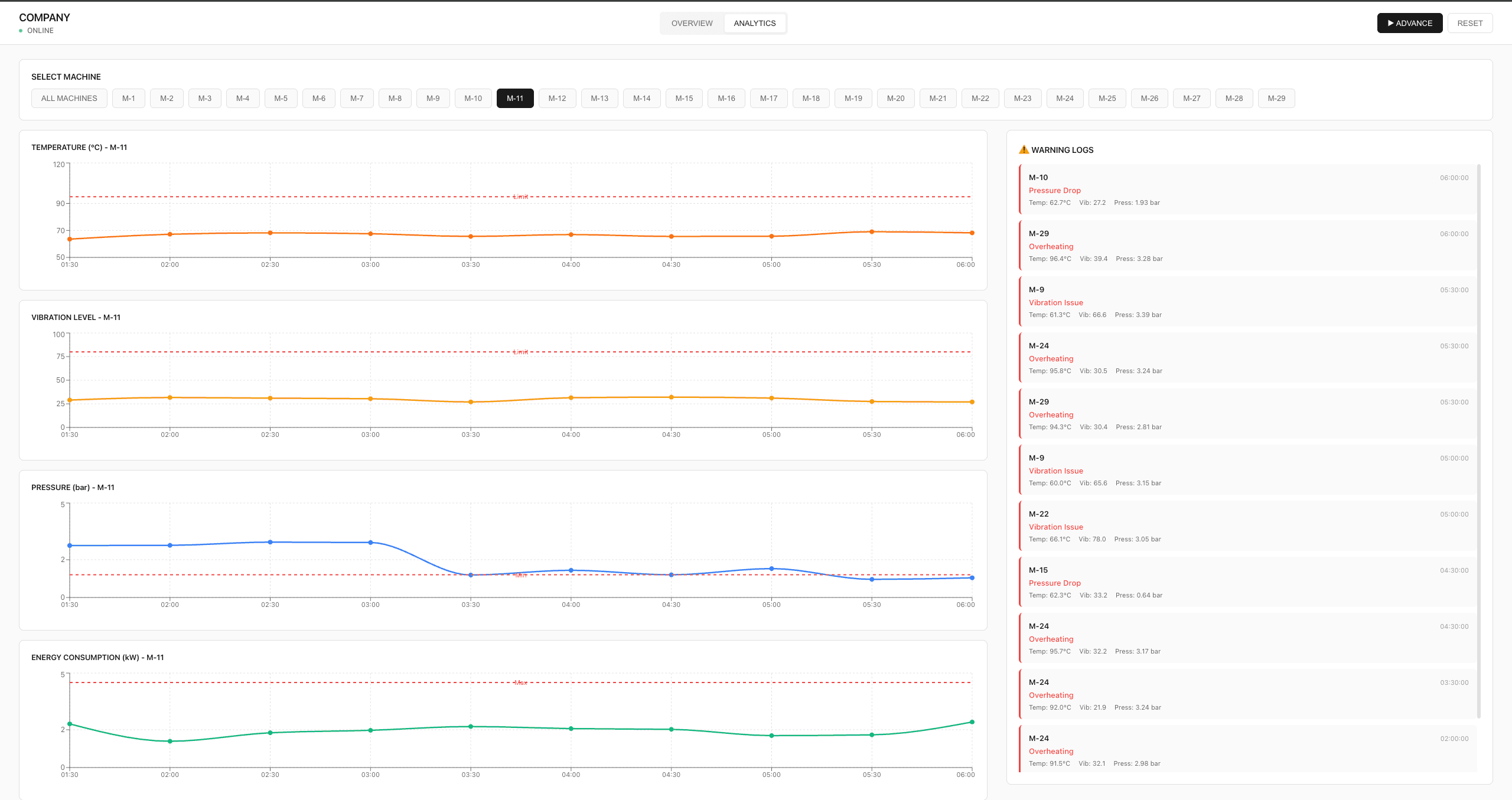

The orionic team designed and delivered a real-time warehouse monitoring dashboard that serves as a unified intelligence layer for all industrial equipment. The platform connects directly to the facility’s IoT sensor network and transforms continuous data streams — temperature, vibration, pressure, and energy consumption — into an actionable visual overview of machine health. At the center of the solution is an interactive floor plan that mirrors the warehouse layout. All 29 machines are represented as color-coded indicators that update every two seconds: green for normal operation, orange for early anomalies, and red for critical faults. Users can zoom into specific zones, inspect live sensor values on hover, and instantly identify where intervention is required. A dedicated machine overview panel provides a structured snapshot of each device’s current status. Operators can review temperature, vibration, pressure, and energy readings for every machine without navigating logs or manual reports, enabling faster and more informed decision-making on the floor. For long-term performance management, the system includes an analytics workspace that tracks reliability trends across the warehouse. Historical charts highlight how sensor values evolve over time and which machines generate the most anomaly events, helping maintenance teams detect degradation patterns and plan service proactively. All detected anomalies are recorded in a centralized event log with precise timestamps, affected machines, and the sensor metrics that triggered the alert. This creates a transparent history of equipment behavior, supports root-cause analysis, and simplifies documentation of maintenance actions. The dashboard operates entirely in real time, refreshing all data every two seconds to ensure continuous situational awareness. It integrates seamlessly with the client’s existing IT environment and was delivered with complete documentation and onboarding support to accelerate adoption across operational teams.

Results & Effects

The deployment of our Real-Time Industrial Warehouse Monitoring system transformed the client’s operational visibility and maintenance workflow. By automatically detecting abnormal throughput patterns, the system enabled maintenance teams to act before issues escalated into downtime events. This shift from reactive troubleshooting to proactive intervention reduced unplanned stoppages and improved overall line stability. Supervisors now have a single, real-time view of performance across all monitored lines, allowing them to allocate staff and maintenance resources with greater precision. Instead of relying on manual checks or delayed reports, operators receive immediate, actionable alerts, reducing response times and preventing production bottlenecks. The result is a warehouse environment that is more reliable, more predictable, and easier to manage. Critical insights that previously required constant human attention are now surfaced automatically, enabling the client to increase throughput consistency, streamline daily operations, and build a stronger foundation for future predictive-maintenance initiatives.